Fu Style Galunggung Steel Conveyor Chain kalawan Quality High

Fu Style Galunggung Steel Conveyor Chain kalawan Quality High

Kategori

ranté link buleud, ranté link baja buleud, ranté pertambangan link buleud, DIN 22252ranté pertambangan, ranté conveyor pertambangan, sistem ranté bar hiber

Aplikasi

Armored Face Conveyors (AFC), Beam Stage Loaders (BSL), mesin header jalan, bajak batubara, jsb.

Salaku nagara produksi batubara No. pabrik ranté SCIC urang kalawan na 30 taun babak baja link ranté sajarah produksi geus pinuh aub kana suplai industri batubara Cina; ranté link buleud urang geus jadi jauh ogé katampa tur dipaké ku sakabéh batubara utama & pausahaan pertambangan ngaliwatan Cina.

kualitas ranté link baja buleud kami geus ensured ngaliwatan unggal hambalan produksi ranté, ti bar baja alloy sora mun fabrikasi link tepat ku robot, ti las butt flash komputerisasi ka quenching dirancang ogé & tempering panas-perlakuan (ngahasilkeun kakuatan dipikahoyong tur karasa permukaan), ti test buktina kana tés mékanis dina verifying kualitas permukaan & batin.

SCIC ranté link buleud dijieun nurutkeun Cina GB / T-12718 baku sarta Sarat Téknis pabrik, kitu ogé DIN 22252 atanapi GOST 25996 standar sarta spésifikasi klien.

ranté link babak SCIC dipaké pikeun Armored raray Conveyors (AFC), Beam Panggung Loaders (BSL), mesin header jalan, bajak batubara jeung alat-alat séjén anu merlukeun jenis ieu ranté.

Lapisan anti korosif (contona, galvanisasi anu dicelup panas) nyababkeun turunna sipat mékanis ranté, ku kituna aplikasi tina palapis anti korosif kedah tunduk kana perjanjian pesenan antara anu mésér sareng SCIC.

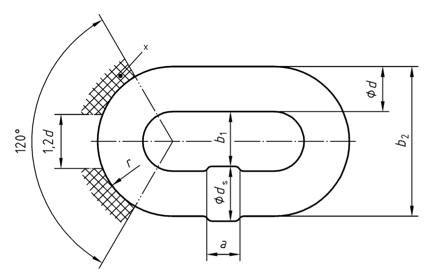

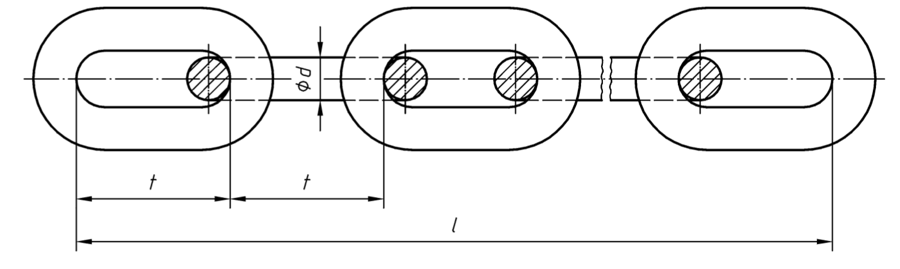

angka 1: ranté link buleud

meja 1: dimensi ranté link buleud

| ukuran link (opp. Weld) | pitch | lebar link | ukuran las link | beurat unit | ||||

| nominal | kasabaran | nominal | kasabaran | batin | luar | diaméterna | panjangna | |

| 10 | ± 0.4 | 40 | ± 0,5 | 12 | 34 | 10.8 | 7.1 | 1.9 |

| 14 | ± 0.4 | 50 | ± 0,5 | 17 | 48 | 15 | 10 | 4.0 |

| 18 | ± 0,5 | 64 | ± 0,6 | 21 | 60 | 19.5 | 13 | 6.6 |

| 19 | ± 0,6 | 64.5 | ± 0,6 | 22 | 63 | 20 | 13 | 7.4 |

| 22 | ± 0,7 | 86 | ± 0,9 | 26 | 74 | 23.5 | 15.5 | 9.5 |

| 24 | ± 0,8 | 86 | ± 0,9 | 28 | 79 | 26 | 17 | 11.6 |

| 26 | ± 0,8 | 92 | ± 0,9 | 30 | 86 | 28 | 18 | 13.7 |

| 30 | ± 0,9 | 108 | ± 1.1 | 34 | 98 | 32.5 | 21 | 18.0 |

| 34 | ± 1.0 | 126 | ± 1.3 | 38 | 109 | 36.5 | 23.8 | 22.7 |

| 38 | ± 1.1 | 126 | ± 1.3 | 42 | 121 | 41 | 27 | 30.1 |

| 38 | ± 1.1 | 137 | ± 1.4 | 42 | 121 | 41 | 27 | 29.0 |

| 42 | ± 1.3 | 137 | ± 1.4 | 48 | 137 | 45 | 30 | 36.9 |

| 42 | ± 1.3 | 146 | ± 1,5 | 48 | 137 | 45 | 30 | 36.0 |

| 42 | ± 1.3 | 152 | ± 1,5 | 46 | 133 | 45 | 30 | 35.3 |

| catetan:Lranté ukuran arger sadia on panalungtikan. | ||||||||

meja 2: sipat mékanis ranté link buleud

| ukuran ranté | ranté kelas | kakuatan uji | elongation handapeun gaya uji | kakuatan megatkeun | elongation dina narekahan | defleksi minimum |

| 10 x 40 | S | 85 | 1.4 | 110 | 14 | 10 |

| SC | 100 | 1.6 | 130 | |||

| SCC | 130 | 1.9 | 160 | |||

| 14 x 50 | S | 150 | 1.4 | 190 | 14 | 14 |

| SC | 200 | 1.6 | 250 | |||

| SCC | 250 | 1.9 | 310 | |||

| 18 x 64 | S | 260 | 1.4 | 320 | 14 | 18 |

| SC | 330 | 1.6 | 410 | |||

| SCC | 410 | 1.9 | 510 | |||

| 19 x 64,5 | S | 290 | 1.4 | 360 | 14 | 19 |

| SC | 360 | 1.6 | 450 | |||

| SCC | 450 | 1.9 | 565 | |||

| 22 x 86 | S | 380 | 1.4 | 480 | 14 | 22 |

| SC | 490 | 1.6 | 610 | |||

| SCC | 610 | 1.9 | 760 | |||

| 24 x 86 | S | 460 | 1.4 | 570 | 14 | 24 |

| SC | 580 | 1.6 | 720 | |||

| SCC | 720 | 1.9 | 900 | |||

| 26 x 92 | S | 540 | 1.4 | 670 | 14 | 26 |

| SC | 680 | 1.6 | 850 | |||

| SCC | 850 | 1.9 | 1060 | |||

| 30 x 108 | S | 710 | 1.4 | 890 | 14 | 30 |

| SC | 900 | 1.6 | 1130 | |||

| SCC | 1130 | 1.9 | 1410 | |||

| 34 x 126 | S | 900 | 1.4 | 1140 | 14 | 34 |

| SC | 1160 | 1.6 | 1450 | |||

| SCC | 1450 | 1.9 | 1810 | |||

| 38 x 126 | S | 1130 | 1.4 | 1420 | 14 | 38 |

| SC | 1450 | 1.6 | 1810 | |||

| SCC | 1810 | 1.9 | 2270 | |||

| 42 x 137 | S | 1390 | 1.4 | 1740 | 14 | 42 |

| SC | 1770 | 1.6 | 2220 | |||

| SCC | 2220 | 1.9 | 2770 |